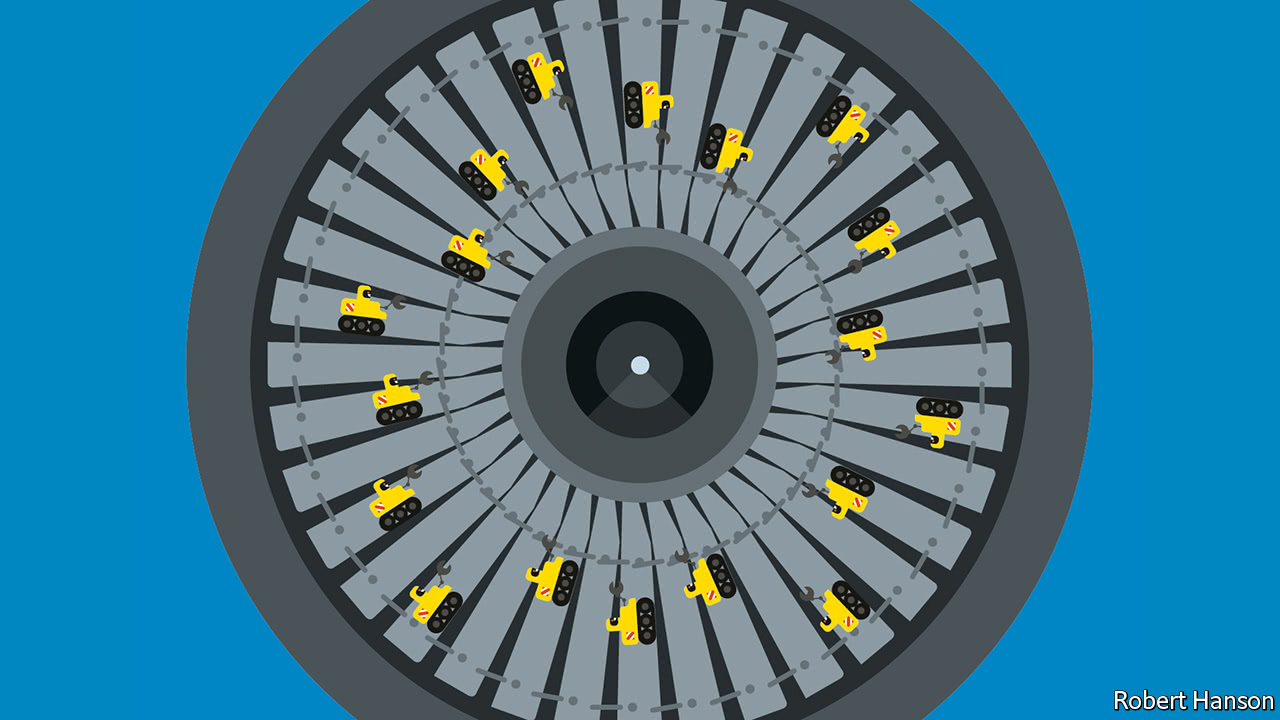

Tiny robots will inspect and fix jet engines from the inside

Sep 29, 2017

Robotic mechanics can go anywhere

IF YOU are reading this while sitting in an aircraft and are of a nervous disposition, do not be alarmed, but the temperature inside the jet engines keeping you aloft probably exceeds the melting point of the materials that those engines are made from. That they do not consequently turn into a molten mess is a feat of modern engineering. It involves a combination of tough alloys and advanced production techniques, such as 3D printing, which allow components to be made with tiny channels through which cooling air circulates. Parts exposed to the most extreme temperatures, which can reach more than 1,300°C, are given additional protection with a coating of special heat-resisting ceramics.

New jet engines are designed to run hot because that results in a more complete combustion, which lowers fuel consumption and cuts emissions. Hot engines, though, need nurturing. Nowadays the three big aircraft-engine makers, General Electric (GE), Rolls-Royce and Pratt & Whitney, usually include servicing as part of their sales, and many jet engines are leased on a “power-by-the-hour” contract. This means regular check-ups and maintenance are in the interests of airlines and producers alike. The difficult bit is inspecting an engine without dismantling it. That requires taking the aircraft to which the engine is attached out of service. And, with a power-by-the-hour contract, when a plane disappears into the workshop, it is not just the airline that loses money, but the engine maker, too. The hunt is therefore on for faster and more efficient ways to keep engines in tip-top condition.

Don Lipkin, a chief scientist at GE Global Research in Niskayuna, New York, and his colleagues Todd Danko and Kori Macdonald, think they have come up with one. They are developing tiny robots which can venture inside an engine to inspect its innards and carry out any necessary repairs. Eventually, these robots may be able to work while a plane is waiting at a gate between flights.

Send in the microbots

Dr Lipkin’s robots are being tested in a laboratory, but he hopes to have them ready to go inside operating aircraft by the end of the year. To start with, they will conduct inspections. Later, once techniques are perfected, they will begin making repairs. Such robots will also be used to inspect and repair GE’s gas turbines. These are jet engines used in power plants to generate electricity, rather than as propulsion devices. But they, too, would benefit from reduced downtime for maintenance.

Inspecting the fan blades that draw air into the front of an engine is reasonably straightforward, because those blades are large and visible. But things get harder the deeper you go. Following the fan are a series of closely packed blades that compress the air before it arrives at the combustion chamber. When the compressed air reaches that chamber, and is mixed with fuel and ignited, the resulting hot gases then blast out of the rear, providing thrust. Some of those gases are diverted through a series of stubby turbine blades near the back of the engine. These, via shafts, turn the fan and the compressor, and thus keep the whole arrangement running.

In a working engine, all of these components are so tightly packed together that sometimes the only way to peek inside is by inserting an endoscope (a camera on a flexible tube) through a hole in the engine’s casing. But the view is limited. The researchers’ robots, however, are small enough to navigate their way around all the various blades, photographing everything they see and relaying the pictures wirelessly to technicians. Then, once the pictures have been analysed, the robot itself can often effect a repair.

The team’s robots come in several varieties. One is about the size of a small envelope and is flexible. It runs along a sort of rack-and-pinion track that is inserted into the back of the engine. The track is made from a long strip of plastic which, with a twisting action, can be flicked between the blades. The robot is attached to the track and employs a toothed drive-mechanism which connects to a series of holes in the plastic strip and permits the device to propel itself along. Once it has arrived at its destination, it expands so that it is gripped between a pair of blades. The track is withdrawn and the robot hitches a ride on the blades as these are rotated manually by technicians. That way it can photograph internal surfaces adjacent to the blades as it passes. Once its job is done, it can be pulled out on a cord.

Another type of robot, a few centimetres square, crawls inside an engine on caterpillar tracks. A third version uses magnetic wheels. These let it grip surfaces made with specialised steels in the cold front section of ground-based gas turbines, and thus work upside down if necessary. All the robots are driven by a human operator using a tablet computer. To repair things, the machines are fitted with tiny arms that reach out and inject ceramic coatings from a cartridge of material to fill in any damaged areas. The robots can also carry small grinding tools, to smooth down ragged surfaces.

Such repairs may not be as permanent as those during a full rebuild, but they are good enough to extend the time an engine can operate between major overhauls. Moreover, data collected by the robots would be used by GE to update the engine’s “digital twin”. These twins are virtual replicas, held on a computer, and contain the latest operating data sent via satellites from sensors mounted inside engines. The twins serve as test beds for spotting problems before they get serious. This means preventive maintenance can be carried out and unscheduled visits to the workshop avoided.

Robots will allow much finer monitoring of an engine’s wear and tear. That varies, according to how aircraft are used—even by particular pilots, some of whom push aircraft engines harder than others do—and where in the world a plane most often operates. Airborne particles, particularly in polluted regions, can block the tiny cooling channels that help stop an engine melting. Wind-blown sand grains in places such as the Middle East subject blades to increased abrasion. Jet engines are already remarkably reliable, with the need for an in-flight shutdown now in the order of once in 20,000 hours of operation, which means a pilot may never experience a failure in his entire career. Tiny robots will make them more so.

Source: The Economist Newspaper